Standing Seam Roof Panel Curving Machine

Standing seam roof panel curving machine also named roof panel crimp curving machine is an auxiliary device for a standing seam roof panel roll forming machine. It is used for curving the standing seam roofing sheet to a required shape with different radius. Generally, a customer will buy a standing seam roof panel roll forming machine with this crimping machine. The crimping machine used to curve the sheet which produced by the roofing sheet roll forming machine. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Standing seam roof panel curving machine also named roof panel crimp curving machine is an auxiliary device for a standing seam roof panel roll forming machine. It is used for curving the standing seam roofing sheet to a required shape with different radius. Generally, a customer will buy a standing seam roof panel roll forming machine with this crimping machine. The crimping machine used to curve the sheet which produced by the roofing sheet roll forming machine. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

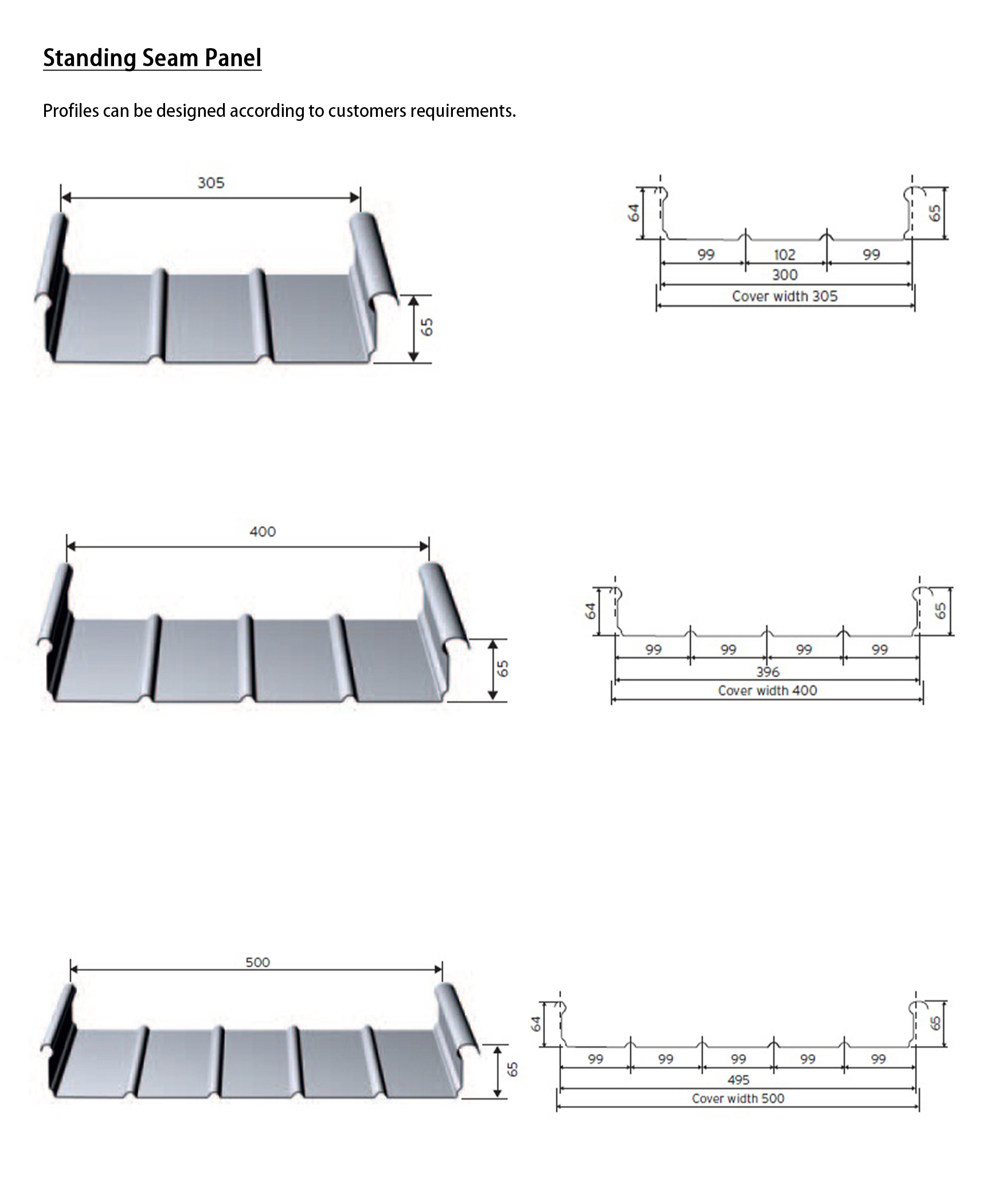

Profile Drawings

Product Parameters

| Standing Seam Roof Panel Curving Machine | ||

|

Raw Material

|

A) Galvanized Coil |

Thickness(MM): 0.3-0.8 or as per customer

|

| B) Aluminium coil, s.s coil | ||

| Yield Strength | 250 – 350 Mpa / 350-550 Mpa Or More | |

| Tensil Stress | 350 Mpa – 550 Mpa Or More | |

| Panel Width | As Per The Panel With Comes From Roll Forming Machine | |

| Feeding Way | Manual Feeding | |

| Curving System | Hydraulic | |

| Material Of Punching Mould | Cr12Mov, Heat Treatment | |

| Automatic | Automatic Set-up Radius, 20 Different Radius Can Be Inputted In Control System At The Same Time (Both Positive Arc And Reversed Arc) | |

| Curving Speed | About 15m/min | |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |