Roofing Sheet Roll Forming Machine Color Steel Corrugated Iron Sheet Roofing Tile Making Machine

This machine adopts steel coils as material and gets roofing sheets after the process of uncoiling, feeding, roll forming, cutting into length and output with table. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

Roofing Sheet Roll Forming Machine adopts steel coils as material and gets roofing sheets after the process of uncoiling, feeding, roll forming, cutting into length and output with table. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

Product Details

Stand Base

Select high quality steel as raw material with high strength and heavy duty, which has strong resistance to deformation.

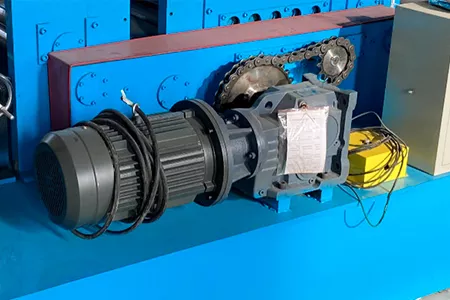

Motor

Adopt top brand motor for drive system, more stable and effective.

Rollers & Shafts

With many years of production experience, more professional and more precision.

Customization

Senior and experienced engineer control the whole process for your customize.

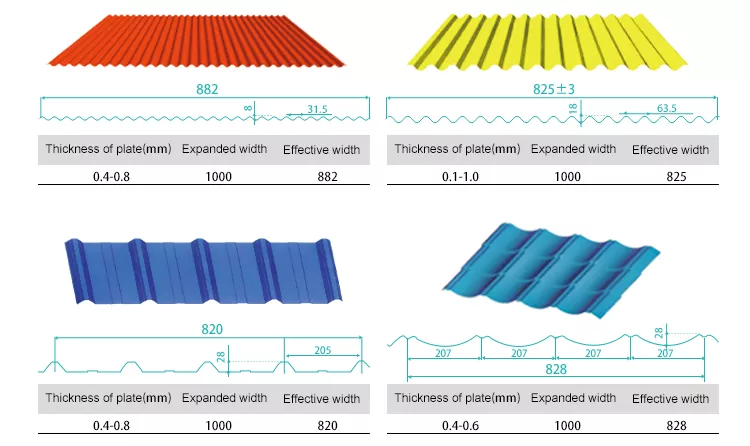

Roofing Sheet Roll Forming Machine Parameters

| Product | Roof sheet roll forming machine |

| Model | Corrugated Trapezoidal (Customizable ) |

| Base Material | GI/GL, PPGI/PPGL, Aluminum Coil |

| Thickness | 0.3mm-0.8mm |

| Effective Width |

600-1250mm (According To Customer Requirements /Customizable)

|

| Roller Station | 14-18 Stations |

| Roller Material | 45# Steel / Bearing Steel/ Cr12Mov |

| Roller Driven Type | By Chain/ Gearbox |

| Color |

According To Customer Requirements / Customizable

|

| Brand | SUNWAY |

| Control System |

Worldwide Famous Brand PLC (Panasonic, Siemens, Delta, etc)

|

| Power | 4KW-5.5KW-7.5KW |

| Frame | 350 H Steel / 400 H Steel |

| Cutting Drive | Hydraulic Drive |

| Cutting&Hydraulic Type |

Type:Double Guide Pillar Hydraulic Cutting.

Hydraulic Pump Station :4kw Blade:Cr12mov HRC:58-62 |

| Way Of Drive | 1.2 inch single chain |

What Is Corrugated Sheet Roll Forming Machine?

A corrugated sheet roll forming machine is a specialized industrial machine used to produce corrugated metal sheets or panels. Corrugated sheets are widely used in various industries, including construction, roofing, and packaging.

The roll forming process involves feeding a continuous strip of metal, typically steel, through a series of rollers and dies. These rollers and dies progressively shape the metal strip into the desired corrugated profile. The machine uses a combination of bending, folding, and shaping actions to create the distinctive wavy or corrugated pattern.

The corrugated sheet roll forming machine typically consists of several components:

- 1.Uncoiler: This component holds the metal coil and feeds it into the machine for processing.

- 2.Feeding system: It transports the metal strip from the uncoiler to the forming section.

- 3.Forming section: This is the heart of the machine, where the metal strip passes through a series of rollers and dies that gradually shape it into the corrugated profile.

- 4.Cutting system: Once the desired length of the corrugated sheet is formed, the cutting system trims the sheet to the required size.

- 5.Control system: It manages the machine’s operation, controlling the speed, length, and other parameters of the production process.

- 6.Stacking or stacking conveyor: This component collects the finished corrugated sheets for further handling or packaging.

Corrugated sheet roll forming machines are highly automated and can produce corrugated sheets in a continuous and efficient manner. They offer precise control over the dimensions and specifications of the final product, ensuring consistent quality and reducing manual labor requirements.

These machines are essential for manufacturers who need to produce large quantities of corrugated sheets for various applications. They enable efficient production, reduce material waste, and contribute to the overall productivity of the manufacturing process.

Application Of Color Steel Roll Forming Machine

A color steel roll forming machine, also known as a color steel roofing sheet roll forming machine, is used to produce color-coated steel sheets or panels. These panels are widely used in the construction industry for roofing and cladding applications due to their durability, aesthetic appeal, and weather resistance. Here are some common applications of color steel roll forming machines:

- 1.Roofing Sheets: Color steel roll forming machines are primarily used to produce roofing sheets. These sheets are made from galvanized steel or aluminum coils and are coated with a layer of color paint or protective coating. The roll forming machine creates the desired profile, such as corrugated or trapezoidal, and applies the color coating. These roofing sheets provide weatherproofing, thermal insulation, and structural support for buildings.

- 2.Wall Cladding: Color steel panels are also used as wall cladding materials in commercial, industrial, and residential buildings. The roll forming machine can produce various profiles and designs that enhance the visual appeal of the building exterior. Color-coated steel panels offer durability, easy maintenance, and resistance to fading, corrosion, and harsh weather conditions.

- 3.Garage Doors: Color steel roll forming machines are used to manufacture garage doors. These doors are made from color-coated steel sheets, which provide strength, security, and aesthetics. The roll forming machine produces the required panel shape and design, and the color coating gives the doors an attractive and long-lasting finish.

- 4.Fencing and Enclosures: Color steel panels produced by roll forming machines are utilized for fencing systems and enclosures. These panels provide privacy, security, and a decorative element to residential, commercial, and industrial properties. The panels can be customized in terms of size, profile, and color to suit specific fencing requirements.

- 5.Agricultural Buildings: Color steel roofing sheets and panels are commonly used in agricultural buildings such as barns, stables, and warehouses. These structures require durable and weather-resistant roofing and cladding materials. Color steel roll forming machines enable the production of customized panels that can withstand harsh agricultural environments and protect the contents of the buildings.

- 6.Portable Cabins and Prefabricated Structures: Color steel panels are used in the construction of portable cabins, modular buildings, and prefabricated structures. These panels offer quick and easy installation, high strength, and design flexibility. The roll forming machine can produce panels with various profiles and sizes to meet the specific requirements of these structures.

Overall, the application of color steel roll forming machines is diverse and crucial in the construction industry, providing a wide range of solutions for roofing, cladding, and other building applications.

How Much Does Corrugated Roll Forming Machine?

The cost of a corrugated roll forming machine can vary depending on several factors such as the machine’s size, complexity, features, brand, and the region where it is purchased. Additionally, prices can change over time due to market fluctuations and technological advancements. It is always recommended to obtain specific pricing information from manufacturers, suppliers, or distributors for accurate and up-to-date cost estimates.

That being said, corrugated roll forming machines typically range in price from several thousand dollars to several hundred thousand dollars. Smaller and less complex machines may be on the lower end of the price spectrum, while larger and more advanced machines with additional features and automation capabilities can be more expensive.

It is important to consider that the cost of the machine is just one aspect of the overall investment. Other factors to take into account include shipping or transportation costs, installation and commissioning expenses, training, maintenance, and ongoing operational costs.

To get an accurate price for a corrugated roll forming machine, it is advisable to contact manufacturers or suppliers directly, providing them with specific details about your requirements, such as desired specifications, production capacity, and any additional features you may need. They will be able to provide you with the most accurate pricing information based on your specific needs and location.