Gutter Roll Forming Machine

A gutter roll forming machine is used to produce rain gutters, which are used in the rainwater goods system. The machine is fully automatically controlled by PLC control system, with the advantage of easy operation and fast efficiency. It is a metal water-falling system, which is a collecting ditch on the side of the eaves. Rain gutter roll forming machine are attached to the roof edges and used to draw water down and away from the house and its foundation. Most gutters consist of sections of gutter, drop outlets and downspouts.

A gutter roll forming machine is used to produce rain gutters, which are used in the rainwater goods system. The machine is fully automatically controlled by PLC control system, with the advantage of easy operation and fast efficiency. It is a metal water-falling system, which is a collecting ditch on the side of the eaves. Rain gutter roll forming machine are attached to the roof edges and used to draw water down and away from the house and its foundation. Most gutters consist of sections of gutter, drop outlets and downspouts.

Gutters can be constructed out of Aluminum, galvanized steel, painted steel, Galvanize, Stainless steel, etc. Thickness of downspout and gutter could be 0.4mm-0.8mm, 0.8-1.5mm. In rainwater goods system, we are able to manufacture more machines like downspout or down pipe roll forming machine, etc.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

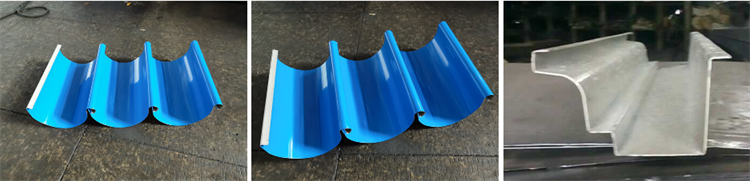

Profile Drawings

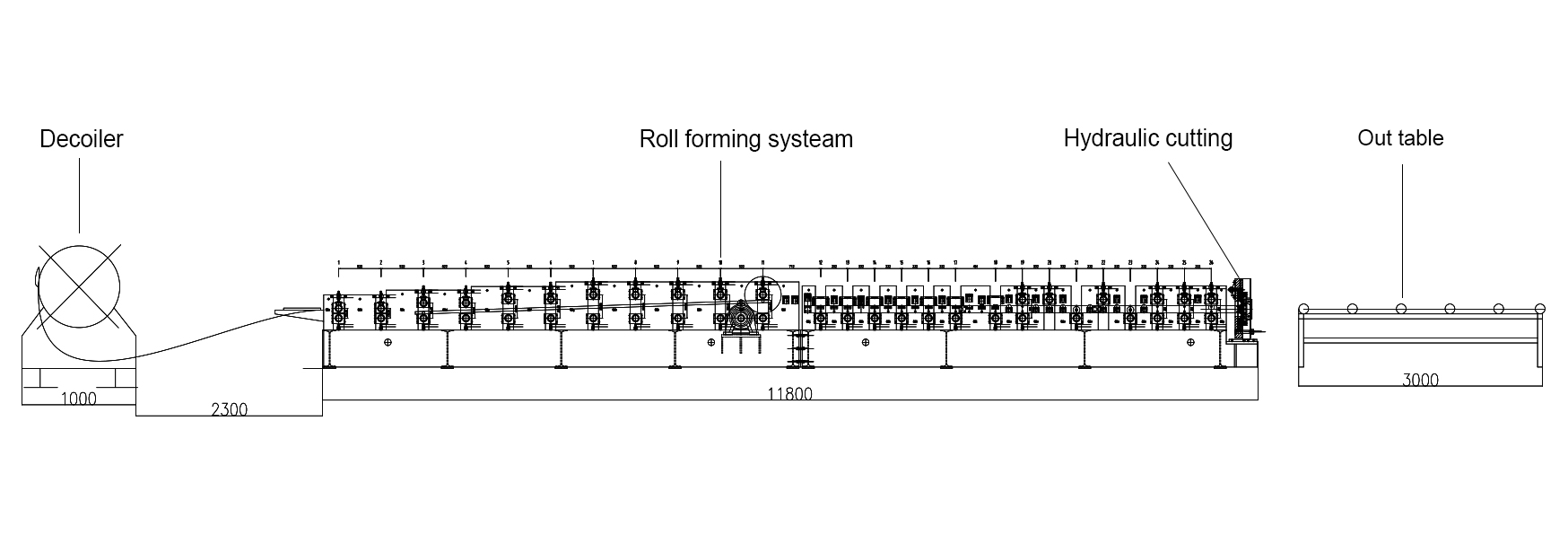

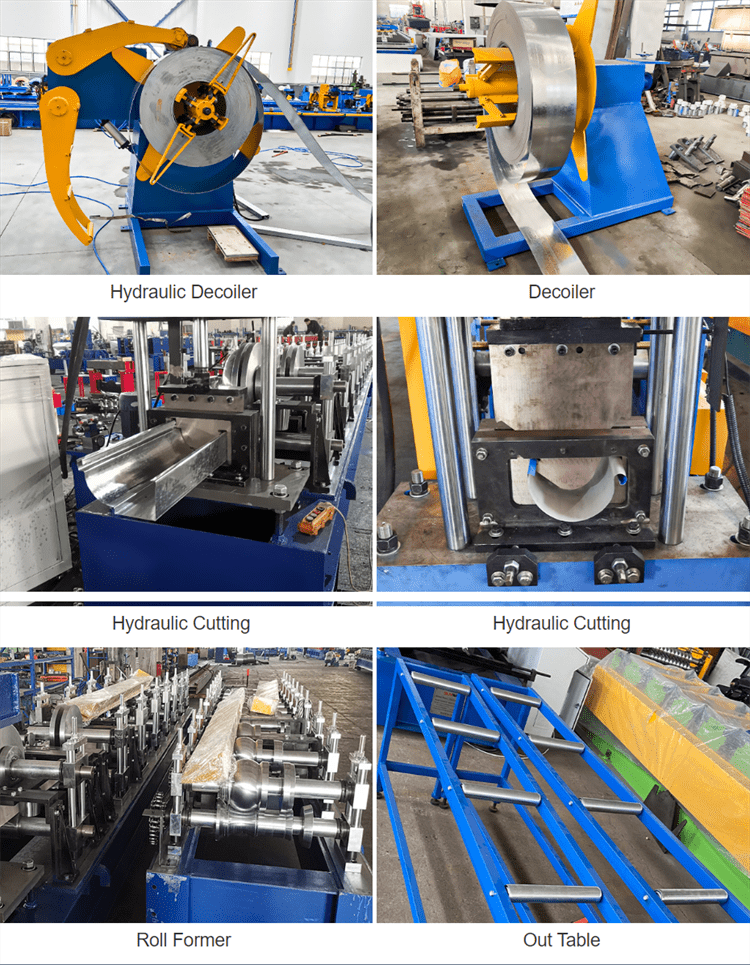

Production Line

Product Details

Product Parameters

| Gutter Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 0.3-0.8 According To Your Requirement

|

| B) PPGI, PPGL | ||

| Yield Strength | 250 – 350 Mpa / 350-550Mpa | |

| Tensil Stress | 350 Mpa-550 Mpa | |

| Coil Width | As Per The Detailed Profile | |

| Forming Speed | 10-15 m/min | * Or According To Your Requirement |

| Forming Station | 10–20 Stations | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Individual Station (Optional) |

| Rollers’ Material | 45# | |

| Cutting System | Hydraulic Post Cut | * Hydraulic Servo Tracking Cutter (Optional) |

| Output Way | Roller Table | |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application