Double Layer Panel Roll Forming Machine

Double layer roll forming machine is mainly used to produce roof panels, which has two layers and produce two different roof / wall profiles. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Double layer roll forming machine is mainly used to produce roof panels, which has two layers and produce two different roof / wall profiles. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

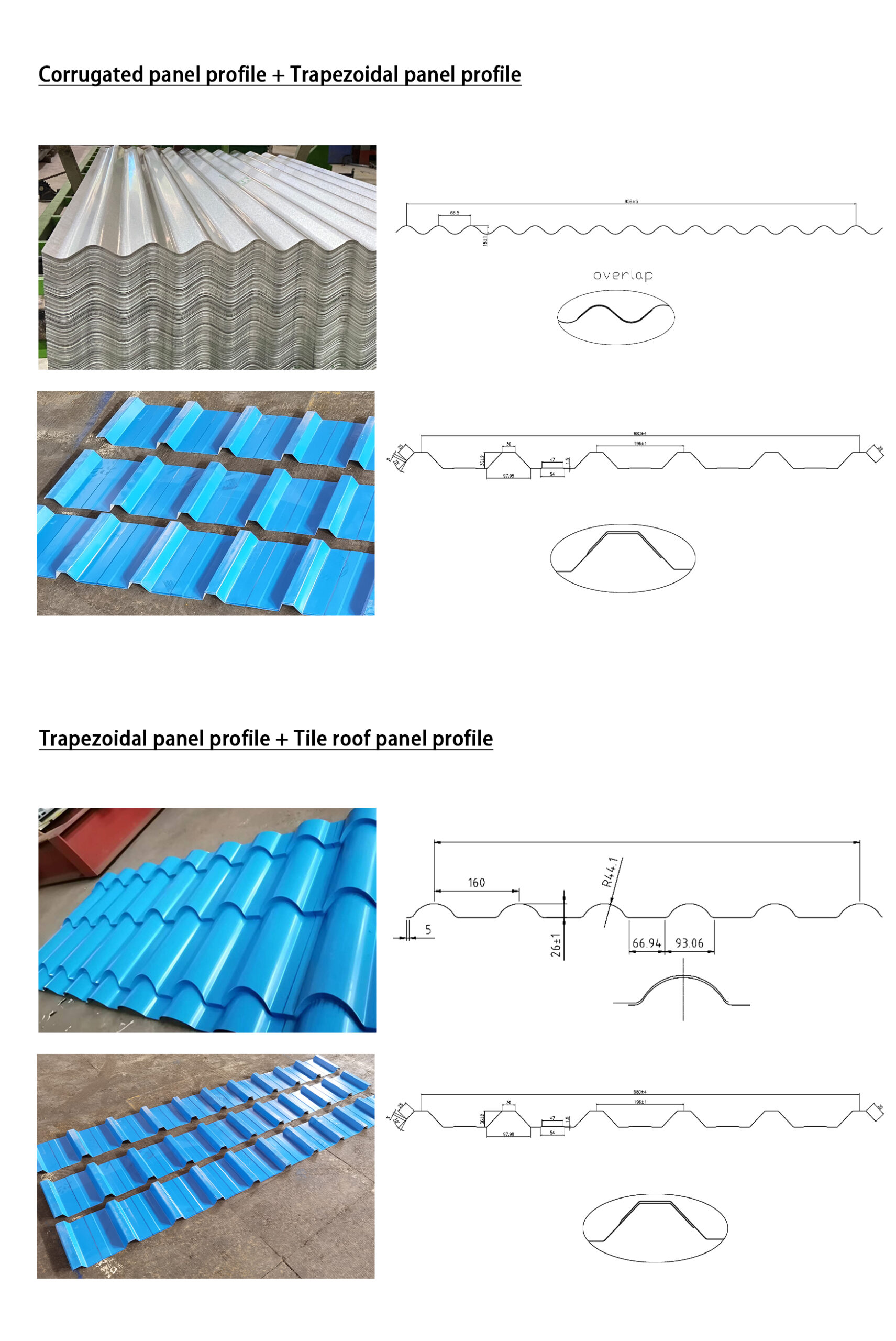

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile, glazed tile, metal deck, wall panel, standing seam, K span and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

Profile Drawings

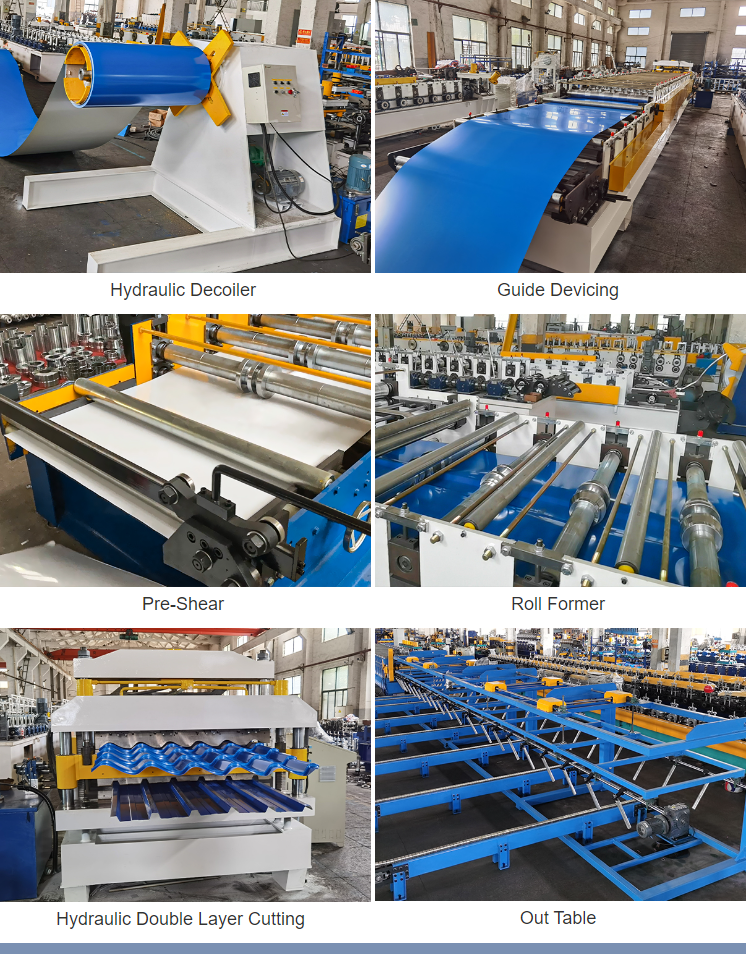

Production Line

Product Details

Product Parameters

|

Double Layer Panel Roll Forming Machine

|

||

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM): 0.3-0.8 According To Your Requirement

|

|

B) PPGI, PPGL

|

||

|

Yield Strength

|

250 – 350 Mpa / 350-550Mpa

|

|

|

Tensil Stress

|

350 Mpa-550 Mpa

|

|

|

Coil Width

|

914mm, 1000mm, 1200mm, 1220mm, 1250mm etc

|

|

|

Forming Speed

|

6-10 (m/min)

|

* Or According To Your Requirement

|

|

Forming Station

|

Two Layers

16-20 Stations for Each Layer |

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Individual Station (Optional)

|

|

Rollers’ Material

|

45#

|

|

|

Cutting System

|

Hydraulic Post Cut

|

* Hydraulic Servo Tracking Cutter (Optional)

|

|

Output Way

|

Roller Table

|

* Auto Stacker (Optional)

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz 3ph

|

* Or According To Your Requirement

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirement

|