Oem Gutter Roll Forming Machine

Oem Gutter Roll Forming Machine

Feb 02, 2024

oem gutter roll forming machine systems enable efficient production of long continuous eavestrough sections used extensively for roof drainage management in buildings. This article provides detailed technical guidance on oem gutter roll forming machine working, selection, installation, comparisons, and more.

Introduction Of Oem Gutter Roll Forming Machine

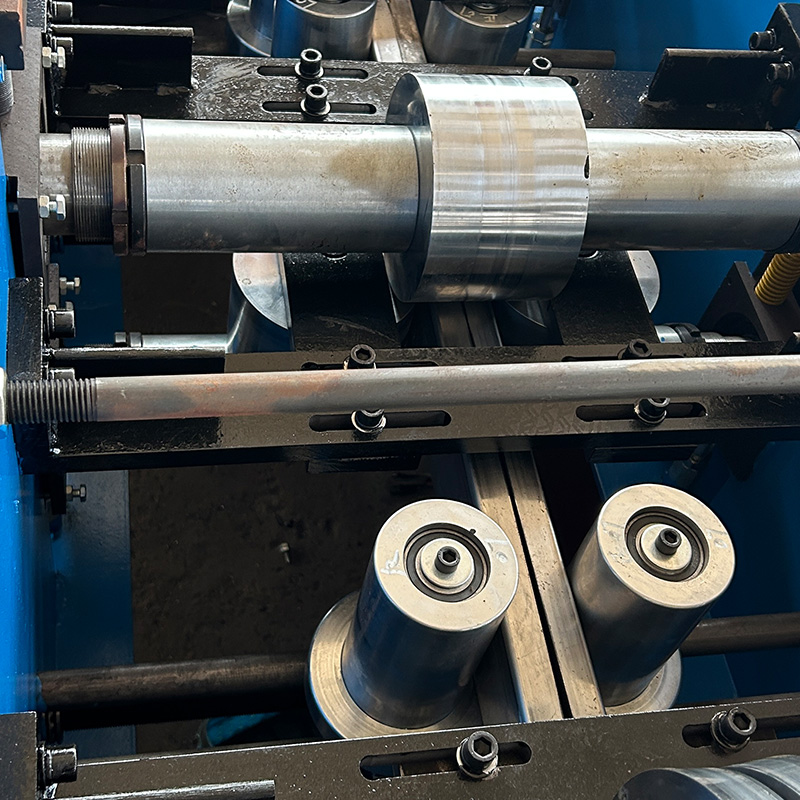

Gutter roll formers utilize a series of roller dies to gradually shape metal coil feedstock into various rain gutter profile geometries. Precision in-line punching and cutting stations provide finished ready-to-install components.

Benefits

- High production rates with low waste

- Dimensional consistency and quality control

- Applicable for various metals like steel, aluminium

- Versatile size adjustments

- Lower operational skill requirement

- Just-in-time inventory production

This guide covers key technical parameters for optimal gutter roll former selection, operation, and maintenance.

Working Principle

The working steps involve:

1. Metal Coil Loading

Prefab metal coils of materials like galvanized steel, zinc alloy coated steel, or aluminium alloys are loaded on a precision programmable de-coiler.

2. Size Reducing

An initial roller stand accurately sizes the strip width while maintaining tension. This feeds into the pre-cutter module.

3. Roll Forming

The metal strip engages precisely engineered top and bottom roller dies mounted sequentially. Each stand incrementally forms the strip into the desired rain gutter profile – half round, K style, box etc. Modern 3D modelling optimizes the number of stands and die geometries.

4. Punching and Cutoff

In-line punching stations create the required slot patterns for brackets attachment. A final shear then cuts the continuously formed gutters to specified lengths as per order requirements.

5. Stacked Output

Formed and sheared eavestrough pieces are automatically stacked on powered out-feed tables for packaging and transport.

Key Capabilities Of Oem Gutter Roll Forming Machine

1. Profile Options

- Half round gutters – Most common

- ‘K’ style with flat bottom

- Square box styles

- Custom profiles to match applications

2. Size Capacity

- Formed widths from 150 mm to 300 mm in incremental steps

- Strip coil thickness from 0.4 mm to 1.2 mm

- Adjustable length pieces up to 7 meters

- Larger sizes may need custom designs

3. Materials Suitability

- Hot-dip galvanized steel with zinc coating

- Pre-finished painted steel for aesthetics

- Aluminium alloy grades 5xxx, 6xxx

4. Added Features

- In-line punching for brackets

- Mitering attachments for corners

- Scroll bending for decorative ends

- Logo embossing capability

5. Key Quality & Rates

| Parameter | Values |

|---|---|

| Maximum Forming Speed | 40 meters per minute |

| Punching Speed | 25 cycles per minute |

| Length Tolerance | ± 3.0 mm |

| Contour Accuracy | ± 1.0 mm |

Typical Applications

- Residential roof drainage systems

- Low slope commercial roofs

- Rainwater harvesting lines

- Agricultural and greenhouse structures

And many more! Engage OEMs to customize for special application requirements.

- Vineyard Post Roll Forming Machine

- Auto Size Changeable Sigma Purlin Roll Forming Machine

- PV Mounting Bracket C Shape Profile Roll Forming Machine

- C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile

- Steel Coil Cut To Length Line Machine

- Steel Coil Cut To Length Line Machine

- Steel Coil Cut To Length Line Machine

- PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

- PV Mounting Bracket Z Shape Profile Roll Forming Machine

Global Supplier Snapshot

| Manufacturer | Location | Production Rates |

|---|---|---|

| FONNTAI | China | Up to 35 mpm |

| UNICO | Taiwan | Up to 25 mpm |

| ILDEX | Turkey | Up to 20 mpm |

| BEHRANG | Iran | Up to 15 mpm |

Involve suppliers early in design development to customize equipment for specific production needs.

Pricing Estimates

Machine Investment

- $65,000 to $180,000

- Profile complexity impacts prices

- Secondary processing capabilities add cost

- Precision requirements affect price

- Level of automation influences price

Operating Costs

- Material coils dominate recurring spend

- Electricity and utilities

- Maintenance spares and labor

Cost Saving Opportunities

- Standardize few profile configurations

- Employ local fabricators where possible

- Carefully evaluate upgrade vs. new buy

- Compare lease vs. buy analysis

- Study total cost of ownership

Balancing production volume, quality, cost and delivery times is key.

Installation & Operation

Best Practices for Installation

- Carefully site and level equipment

- Check engagement and alignment of tooling

- Confirm coil loading and feeding path

- Test initial production thoroughly

- Inspect critical formed lengths and punching

Tips for Productive Operation

- Monitor line speed, strip tension

- Watch for coil defects during payout

- Use proper mists, lubricants on forming dies

- Ensure stacker smoothness

- Conduct preventive maintenance during breaks

Reliability Focus

- Inspect rollers and guides wear

- Check hydraulics, electrics, pneumatics

- Monitor overall rigidity and vibration

- Backup automation data and parameters

Well planned maintenance improves uptime.

Selecting Equipment

Key Selection Parameters

| Parameter | Evaluation Aspects |

|---|---|

| Product Quality | Case studies, testimonials |

| Technical Expertise | Proven gutter profile experience |

| Customization | Flexibility to match specifications |

| Responsiveness | Quote turnaround, after-sales support |

| Reliability | ISO certifications, safety features |

| Value Added | Commissioning support, Training services |

Get detailed proposals from multiple vendors on cost, quality and lead time considerations before ordering equipment.

SWOT Analysis

Strengths

- Continuous, efficient production

- Dimensional consistency

- Low operational skill needs

Weaknesses

- Initial die engineering timelines

- Thickness range limitations

Opportunities

- New materials compatibility

- Building code acceptance

Threats

- Low labor cost competition

- Commoditization unless unique

Gutter roll forming offers optimal productivity for production volumes over 200,000 linear feet annually provided equipment selection and operation is professionally managed.

FAQs

Q: What thickness range can be formed?

A: Up to 1.5 mm thickness for steel and 2.5 mm for softer aluminium is possible directly. Thicker metals require separate rolling first.

Q: What automation options are available?

A: Servo feed upgrades for consistency, monitoring systems to reduce human errors, stacking robots etc. minimize manual intervention.

Q: What testing standards apply for rain gutters?

A: Various durability tests for load capacity confirm designs meet codes like AS/NZS 2904 and EN 1462. Leakage testing ensures water tightness.

Recent Posts

October 26, 2016

The Most Successful Engineering ContractorContact Us To Get The Newest Quotation

Contact us to get the newest quotation. You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.